Sale HDPE pipe production line with silicone inner wall In Kharazmi Industrial City

You can introduce your business services or products in this section.

For this purpose, be in touch with us.

The quality of the polyethylene pipe should be controlled along the production line according to production standards. Even with the best design and use of the finest raw materials, the lack of proper quality control during production can create adverse results from the final product. With a series of extruders (single tube), the pipe can be produced with high quality of PEX, ABS, PPR, PP. The rotating cutting machine can be controlled automatically by the computer . mentioned production lines are simple and reliable, and also are advanced in the world. The types of polyethylene pipe lines according to their sizes are as follows .

With the rapid development of the plastics industry, the market has increased higher standards and requirements for the quality of plastic extrusion products. Guangdong Blesson Precision Machinery Co., Ltd. supplies high-quality PE pipe production lines to customers all over the world with professional technology and continuous innovation. The PE pipe production line from Guangdong Blesson Precision Machinery Co., Ltd. is mainly used in municipal water supply systems, interior water supply systems in buildings, water treatment piping systems, sewage and drainage piping systems, electrical conduits, agricultural irrigation pipe, gas transportation piping system and other fields.

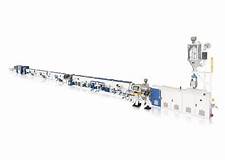

It is used for pipes of water supply , sewage , agriculture , building industry and etc. this line include of single screw extruder , buckle , vacuum tank , cooling tank , haul-off , cutter , stacker . frequently speed control system of extruder , haul-off , vacuum motor , main motor of extruder , all are well known and famous type and also have high efficiency . the production of PE pipe is apparently a simple and easy process but the process of producing a PE pipe deponds on the details that if a small error occurs in the production process , it can lead to a poor quality and unacceptable products. Equipments and spare parts for the production line of polyethylene is one of the most important factors in the quality of the finished product and these equipments must be used with the highest possible quality and ultimately in perfect harmony . production line of Pe should be modern and update , works according to the latest European standards and with the highest level of control , observes all production characteristics , control all components of an excellent product and in case of non-conformance, automatically solve the problem or stop the pipe production process . The precise control of weight along with the reduction of melt fluctuations of exhaust material from the mold in the cross-section and the length of the pipe is one of the most important parameters to be considered when choosing a polyethylene production line. The use of precise and advanced control systems makes this possible .

HDPE silicon core pipe with high density polyethylene (HDPE) and a mixture of silica gel and are formed by the co-extrusion composite, it is a wall with a mixture of silica gel composite cable casing, it smooth inner wall, small frictional resistance, physical properties of good. It has good advantage in respect of the working life and engineering construction. The silicon core pipe can used for highway, railway, electric power, communication, cable pipe and so on

HDPE silicon core pipe with high density polyethylene (HDPE) and a mixture of silica gel and are formed by the co-extrusion composite, it is a wall with a mixture of silica gel composite cable casing, it smooth inner wall, small frictional resistance, physical properties of good. It has good advantage in respect of the working life and engineering construction. The silicon core pipe can used for highway, railway, electric power, communication, cable pipe and so on