Sale Polyethylene pipe iron In Firozkooh

You can introduce your business services or products in this section.

For this purpose, be in touch with us.

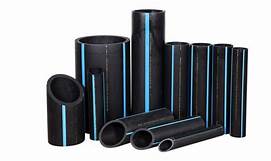

Pipe made of polyethylene and its use in the sector that makes water pipes What are the different types of polyethylene pipes, and what are the benefits of using polyethylene pipes in plumping systems that have led to their widespread adoption Excellent characteristics of the Polypie. Nowadays, one may get a lot of polyethylene pipes at various used hardware shops. These tubes find widespread usage in a variety of different applications. It is highly recommended that you read this essay completely from beginning to finish. Polyethylene is the most widely used kind of plastic worldwide, and products made from polyethylene make up the majority of all consumed plastic. Pipework in industrial manufacturing is one of their most common applications. Due to the significance of this topic, we will devote this article to discussing the many varieties of these pipes as well as the applications for each of them. What is meant by the term polyethylene foam:Polyethylene pipes are comprised of flexible plastic, and the flexibility of polyethylene pipes is one of the primary benefits of these pipes. Because of this flexibility, polyethylene pipes are perfect for installation operations, particularly in situations where flexibility is necessary.

As a result of the various benefits that polyethylene pipes provide, their usage is quite widespread, and new applications for polyethylene pipes are being developed on a daily basis. These applications are imaginative and unusual. HDPE pipes are quite common in a variety of pipeline applications, including urban, industrial, maritime, drilling, and agricultural. This kind of pipeline has been tried and tested in a variety of environments, including above ground, buried (underground), floating, and underwater. Pipes made of polyethylene are versatile enough to carry a wide variety of liquids and gases, including potable water, chemicals, slurry, waste water, and even hazardous waste and compressed gases.The following are some of the reasons for utilizing various kinds of polyethylene pipes, as well as the benefits of doing so:

Routing of cables, coating of fiber optics, protection of power cords, covering of metal pipes, ventilation ducts, and gas distributionTransfer of water via the irrigation systemPolyethylene pipe with two layers of insulation: The internal pressure of any form of double-walled polyethylene pipe may be completely eliminated throughout the process of transporting waste water and liquids. Because this particular kind of polyethylene pipe is strong enough to handle the pressure that is applied from the outside, it is used in a variety of different industries. For instance, spiral polyethylene pipes are a popular choice for use in the building of roads and bridges. The use of double-walled polyethylene tubing has a number of distinct benefits. The manufacturing process is the primary distinction between polyethylene double wall pipe, carrogate double wall pipe, and spiral pipe. All three types of pipe are functionally identical.There is no accumulation of silt in the pipes. Resistant to a variety of chemical gases and liquidsLight as compared to concrete pipes of equal size and weightThere is no need for cumbersome equipment throughout the installation process. Reduce your running expenses and increase the lifespanMade with the most cutting-edge equipment of the highest possible quality Applications for polyethylene pipes include the following:Polyethylene pipe offers a wide range of potential uses in the transmission of fluids in large-scale industrial operations due to the exceptional qualities it has. This polyethylene pipe is now considered to be one of the top options for water supply systems, fire hoses, and other similar applications. When it comes to transferring salt water and sea water, this is the method of choice.

As a result of the various benefits that polyethylene pipes provide, their usage is quite widespread, and new applications for polyethylene pipes are being developed on a daily basis. These applications are imaginative and unusual. HDPE pipes are quite common in a variety of pipeline applications, including urban, industrial, maritime, drilling, and agricultural. This kind of pipeline has been tried and tested in a variety of environments, including above ground, buried (underground), floating, and underwater. Pipes made of polyethylene are versatile enough to carry a wide variety of liquids and gases, including potable water, chemicals, slurry, waste water, and even hazardous waste and compressed gases.The following are some of the reasons for utilizing various kinds of polyethylene pipes, as well as the benefits of doing so:

Option to attach very securely, without leaking, and with great UV protection from the sun, all while maintaining flexibility.has really impressive hydraulic qualities. Costs of upkeep that are minimalThe excellent resistance offered by polyethylene pipes is an additional benefit of using these pipes. Utilizing air compression and spring devices to spring and release pipes is an excellent way to take advantage of this benefit.In water supply construction projects, the use of polyethylene pipes and fittings: